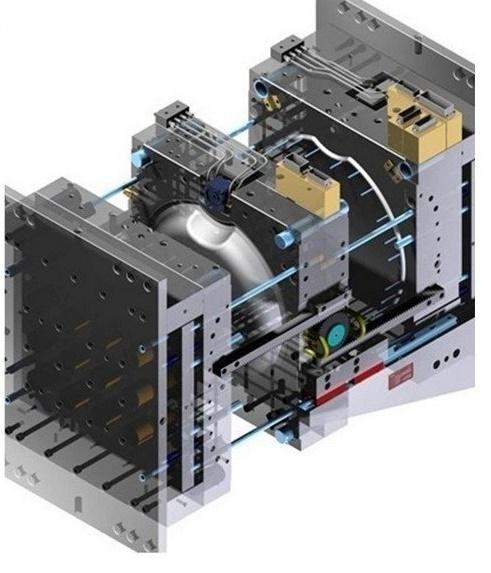

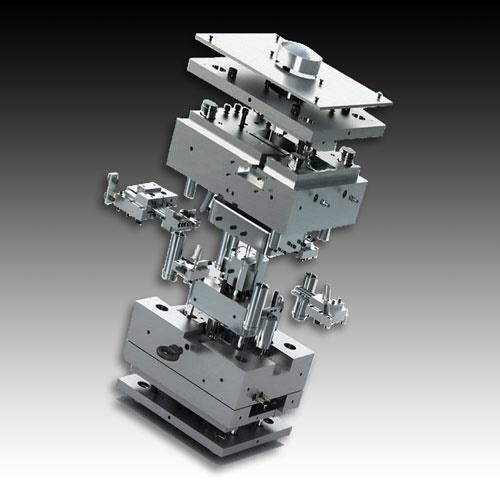

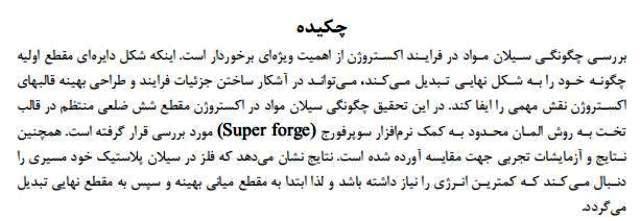

طراحی کامل یک قالب احتمالا چالش برانگیز ترین کار در زمینه پردازش پلاستیک ها و به خصوص در قالب های تزریق پلاستیک به شمار می رود. پارامترهای موثر قالب عبارتند از: کیفیت، عملکرد، سودآوری قطعات پلاستیکی و... همچنین تکنولوژی پیشرفته کامپیوتر و نه پیچیده نرم افزارهای تحلیل (CAE) می تواند جایگزین تجارب مفید مهندسین طراح قالب گردد. به همین دلیل کتاب Castrow به مهندسین پلاستیک خاص اشاره می نماید، در این ویرایش از کتاب 130 طرح قالب و ساخت آن به کتاب افزوده شده است. هر یک از این طرح ها در واقع در صنعت ساخته شده، تست گردیده و محصول پلاستیکی را موفقیت تولید نموده است.

قالب تزریق پلاستیک

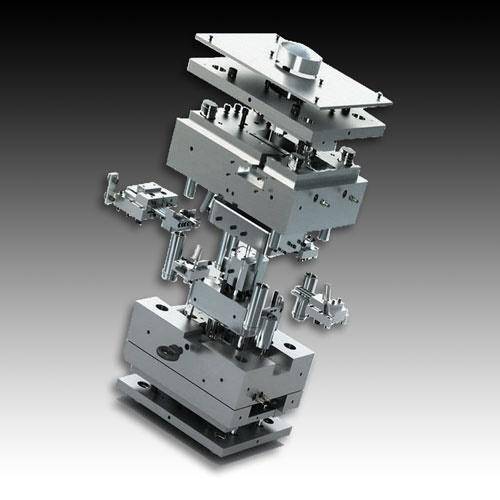

قالب آهنگری و فورج

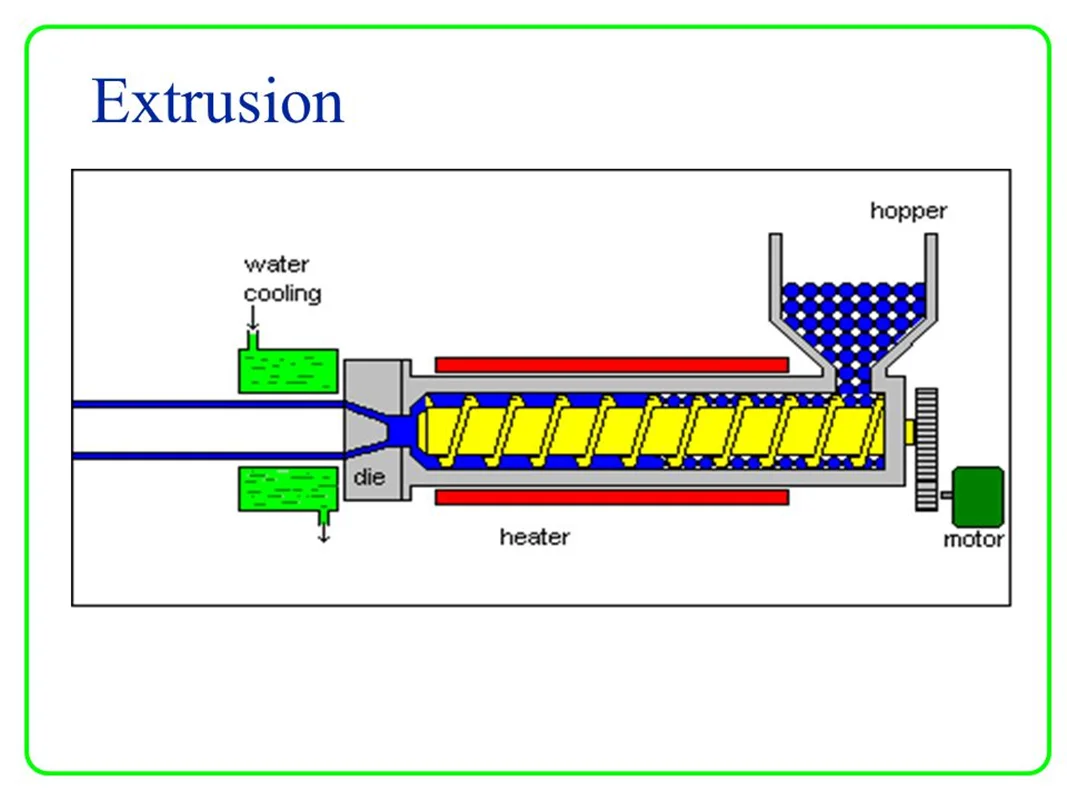

قالب هیدروفرمینگ

کتاب قالب های تزریق به انضمام 130 طرح قالب اثبات شده (Injection Molds, 130 Proven Designs)، یکی از بهترین کتاب ها در زمینه طراحی قالب های تزریق می باشد. موضوعی که در این کتاب بسیار حائز اهمیت است، وجود 130 طرح (نقشه فنی) از قالب های تزریق است که همگی در صنعت طراحی، تست و ساخته شده اند (بخش 3 از فهرست کتاب را در زیر ملاحظه بفرمایید).

قالب فلزی و برش

راهنمای جامع طراحی قالب

مهندسی طراحی قالب های تزریق پلاستیک

طراحان می توانند از این طرح های آماده (نقشه های فنی قالب) در طراحی های خود الگو برداری نمایند و این کتاب می تواند برای طراحان قالب های تزریق بسیار مفید واقع گردد. این کتاب مشتمل بر 326 صفحه، در 3 فصل، به زبان انگلیسی، همراه با تصاویر به ترتیب زیر گردآوری شده است:

Chapter 1: Principles of Mold Design

- Types of Injection Molds

- Types of Runners and Gates

- Temperature Control in Injection Molds

- Types of Ejectors

- Types of Undercuts

- Special Designs

- Standard Mold Components

- Status of Standardization

- Material Selection

- Surface Treatment Methods

- Special Materials

- Molds for Processing Thermosets

- Molds for Processing Elastomers

Chapter 2: Special Design Features of the Mold Examples

Chapter 3: Examples

- Single-Cavity Injection Mold for a Polyethylene Cover

- Two-Cavity Unscrewing Mold for a Glass-Fiber-Reinforced Polyamide Threaded Plug

- Injection Mold for the Body of a Tape-Cassette Holder Made from High-Impact Polystyrene

- Five-Cavity Injection Mold for Tablet Tubes Made from Polystyrene

- Four-Cavity Injection Mold for a Polyamide Joint Element

- Mold Base with Interchangeable Inserts to Produce Standard Test Specimens

- Two-Cavity Rotary Core Mold for a Polyacetal Pipe Elbow

- Hot Runner Injection Mold for Car Front Fender

- Injection Mold for Magnifying Glass Frame with Handle

- Two-Cavity Injection Mold for a Glue Dispenser Made from High- Density Polyethylene (PE-HD)

- Four-Cavity Injection Mold for a Housing Made from Acrylonitrile- Butadiene-Styrene (ABS)

- Four-Cavity Injection Mold for a Nozzle Housing Made from Polyamide

- Single Split Cavity Mold for a Threaded Plug Made from Polyacetal

(POM) - Molding a Container with External Undercuts

- Injection Mold with Reduced Opening Stroke for Milk Crates

- Two-Cavity Injection Mold for Recessed Refrigerator Handles Made from Polyamide

- Injection Mold for a Grass Catcher Made from Polypropylene

- Injection Mold for Hose Connectors Made from Polyamide 6.6

- Two-Cavity Injection Mold for the Coil Form of an Auxiliary Relay

- Two-Cavity Injection Mold for a Housing Made from Polypropylene

- Four-Cavity Injection Mold for Producing a Thrust Screw Made from Polyacetal

- Mold for a Pump Housing and Pump Piston Made from Polyacetal

- Hot-Runner Injection Mold for Two Film Spools Made from High- Impact Polystyrene

- Injection Mold for an Angle Fitting

- Mold for Bushings with Concealed Gating

- Injection Mold for the Valve Housing of a Water-Mixing Tap Made from Polyacetal

- Mold for a Lid with Three Threads Made from Polyacetal

- Two-Cavity Injection Mold for Coupling Sleeves Made from Polyamide

- Injection Mold for the Housing of a Polypropylene Vegetable Dicer

- Two-Cavity Injection Mold for a Polypropylene Toy Tennis Racket

- Two Injection Molds with Two-Step Ejection Process

- Injection Mold for a Polypropylene Container with a Threaded Neck

- Three-Plate Injection Mold with Stripping Device for a Precision

Magazine - Three-Cavity Injection Mold for a Cosmetic Cream Container with a

Threaded Lid - Mold for a Polyamide V-Belt Pulley

- Cavity Hot-Runner Stack Mold for Yoghurt Cups Made from Polypropylene

- Cavity Stack Mold for Covers Made from Polypropylene

- Cavity Stack Mold for a Case Made from Polypropylene

- Four-Cavity Hot-Runner Stack Mold for Producing Automotive Inner

Sill Trim Made from Polypropylene - Hot-Runner Stack Mold for a Water Distribution Block Made from

Polypropylene - Cavity Stack Mold for Lozenge Box Made from Polystyrene

- Two-Cavity Injection Mold for a Back Light Casing Made from ABS

- Cavity Stack Mold with a Hot-Runner System for Runnerless

Molding of Polystyrene Container Lids Using Direct Edge Gating - Cavity Hot-Runner Stack Mold for Dessert Cups Made from

Polypropylene - Hot-Runner Mold for Bumper Fascia Made from Thermoplastic

Elastomer - Four-Cavity Hot-Runner Mold for Threaded Covers Made from SAN

- Two-Cavity Hot-Runner Mold for Trim Bezels Made from ABS

- Four-Cavity Hot-Runner Mold for Control Flap Made from Polyacetal

Copolymer - Cavity Hot-Runner Mold for Seals Made from Thermoplastic

Elastomer (TPE) - Eight-Cavity Hot-Runner Mold for PP Toothpaste Dispenser

- Two-Cavity Hot-Runner Mold for Tubs Made from Polyethylene

- Two-Cavity Hot-Runner Mold for Production of Connectors Made

from Polycarbonate - Four-Cavity Hot-Runner Unscrewing Mold for Cap Nuts Made from

Polyacetal (POM) - Four-Cavity Hot-Runner Mold with a Special Ejector System for

a Retainer Made from Polypropylene - Cavity Two-Component Injection Mold for Microswitch

Covers Made from Polyamide and Thermoplastic Elastomer - Cavity Hot-Runner Mold for Production of Packings Made from

Polyethylene - Cavity Hot-Runner Mold with Edge Gates for Bushings Made from

Polyacetal Copolymer - Hot-Runner Mold for a Polycarbonate Sight Glass

- Two-Component Injection Mold for Drink Can Holders Made from

Polypropylene and Ethylene-Propylene Terpolymer - Hot-Runner Mold for Polypropylene Clamping Ring with Internal

Undercut around the Circumference - Injection Mold for Compact Discs Made from Polycarbonate

- Single-Cavity Injection Compression Mold for a Cover Plate Made

from Unsaturated Polyester Resin - Two-Cavity Injection Compression Mold for a Housing Component

Made from a Thermosetting Resin - Injection Compression Mold for a Plate Made from Melamine Resin

- Five-Cavity Unscrewing Mold for Ball Knobs Made from a Thermoset

Resin - Four-Cavity Injection Mold for a Thin-Walled Housing Made from a

Thermosetting Resin - Thermoset Injection Mold for a Bearing Cover

- Eight-Cavity Injection Mold for Manufacturing Bellows Made from

Silicone Rubber - Two Injection Molds for Overmolding of Polyamide Tubing for

Automobile Power Window Operators - Single-Cavity Injection Mold for a Housing Base Made from Polycarbonate

- Connector of Glass-Fiber-Reinforced Polyamide with Opposing

Female Threads - Cylindrical Thermoplastic Container with Reduced-Diameter Opening a Study in Part Release

- Single-Cavity Injection Mold for a Lighting Fixture Cover Made from

Polymethylmethacrylate (PMMA) - Injection Mold for a Housing of Polycarbonate with a Thread Insert

- Mold for Long, Thin, Tubular Parts Made from Polystyrene

- Insulated Runner Mold for Three Specimen Dishes Made from

Polystyrene - Single-Cavity Injection Mold for a Polypropylene Emergency Button

- Eight-Cavity Injection Mold for Battery Caps with Undivided External

Thread and Sealing Cone - Injection Mold for a Curved Pouring Spout

- Injection Mold for an ABS Spectacle Frame

- Two-Cavity Injection Mold for a Cover Made from Glass-Fiber

Reinforced Polyamide - Two-Cavity Two-Component Injection Mold for a PC/ABS Bezel

with a PMMA Window - Two-Cavity Injection Mold for Runnerless Production of Polycarbonate Optical Lenses

- Injection Mold with Hydraulic Core Pull for a Cable Socket

- Eight-Cavity Hot-Runner Injection Mold for Polyethylene Caps

- Four-Cavity Injection Mold for Pipets

- Two-Cavity Mold for Water Tap Handles

- Two-Cavity Injection Mold for the Automatic Molding of Conveyor

Plates onto a Wire Cable - Cavity Hot-Runner Mold for Producing Curtain-Ring Rollers

Made from Polyacetal Copolymer - Injection Mold with Attached Hydraulic Core Pull for Automatic

Measuring Tube Production - Three-Cavity Injection Mold for Liquid-Measuring Cylinders

- Cavity Hot-Runner Injection Mold for Polyacetal Spool Cores

- Two-Cavity Hot-Runner Mold for Loudspeaker Covers Made from

Polyacetal - Injection Mold with Air Ejection for Polypropylene Cups

- Molds for Manufacturing Optical Lenses

- Two-Cavity Injection Mold for a Polycarbonate Steam Iron Reservoir

Insert - Injection Mold with Pneumatic Sprue Bushing for a Headlight Housing

Made from Polypropylene - Injection Mold for a Mounting Plate (Outsert Technique)

- Twelve-Cavity Hot-Runner Mold for a Polyphthalamide (PPA)

Microhousing - Two-Cavity Injection Mold for Handle Covers Made from Glass-

Fiber-Reinforced Polyacetal - Four-Cavity Injection Mold for Thin-Walled Sleeves Made from

Polyester - Injection Mold for a Thermoplastic Microstructure

- Injection Mold for Production of Adjustable Climate Control Vents

via 3-Shot Molding - Two-Cavity Hot-Runner Injection Mold for an ABS Cover

- Six-Cavity Injection Mold for Retaining Nuts with Metal Inserts

- Single-Cavity Injection Mold for a Switch Housing Made from

Polyacetal - Single-Cavity Injection Mold for a Snap Ring Made from Polyacetal

- Injection Mold for High-Density Polyethylene (PE-HD) Trash Can

Lids - Single-Cavity Hot-Runner Injection Mold for an Air Vent Housing

Made from Acrylonitrile Butadiene Styrene (ABS) - Single-Cavity Hot-Runner Injection Mold for an ABS Housing

- Single-Cavity Runnerless Injection Mold for a Polystyrene Junction

Box - Four-Cavity Hot-Runner Injection Mold for a Polyamide 6,6 Joining

Plate - Cavity Hot-Runner Stack Mold for Hinged Covers

- Cavity Mold with Cold-Runner System for Liquid Silicone Rubber

(LSR) Caps - Two-Cavity Injection Mold for a Styrene-Acrylonitrile Safety Closure

- Four-Cavity Unscrewing Mold for Threaded Polypropylene Closures

- Four-Cavity Injection Mold for Polyester Dispenser Heads

- Two-Cavity Injection Mold for PMMA Lighting Fixture Cover

- Two-Cavity Injection Mold for Polyacetal Hinges

- Eight-Cavity Injection Mold for PE-HD Threaded Caps

- Two-Cavity Cold-Runner Injection Mold for Thermoset Ashtrays

- Single-Cavity Mold for a Polypropylene Cutlery Basket

- Two-Cavity Injection Mold for Cover Plates

- Single-Cavity Injection Mold for Polystyrene Caps (Mold Frame with

Interchangeable Inserts) - Single-Cavity Injection Compression Mold for Thermoset V-Belt

Pulley (Injection Transfer Mold) - Eight-Cavity Cold-Runner Injection Mold for Thermoset Elastomer

Strain Reliefs - Single-Cavity Injection Mold for a PE-HD Clothes Hanger Produced

via Gas-Assisted Injection Molding - Single-Cavity Injection Mold for a Syringe Shield Produced via

Metal Injection Molding (MIM) - Three-Station Mold for a Handtool Handle

- Four-Cavity Injection Mold for Couplings Produced via Metal

Injection Molding (MIM)

جهت دانلود کتاب قالب های تزریق به انضمام 130 طرح قالب اثبات شده (Injection Molds, 130 Proven Designs)، بر لینک زیر کلیک نمایید.

قالب های تزریق به انضمام 130 طرح قالب آماده اثبات شده

اگر به فراگیری مباحث مشابه مطلب بالا علاقهمند هستید، آموزشهایی که در ادامه آمدهاند نیز به شما پیشنهاد میشوند:

تکنولوژی ماشینکاری

تکنولوژی ماشینکاری ماشین های ابزار

ماشین های ابزار راهنمای قوی و جامع سالیدورکس 2015 برای کاربران مبتدی و سطح متوسط

راهنمای قوی و جامع سالیدورکس 2015 برای کاربران مبتدی و سطح متوسط اصول تفکیک آپارتمان ها و نحوه کار با نرم افزار واسط کاداستر

اصول تفکیک آپارتمان ها و نحوه کار با نرم افزار واسط کاداستر روش های اجزاء محدود مقدماتی پروفسور عیسی سلاجقه

روش های اجزاء محدود مقدماتی پروفسور عیسی سلاجقه جزوه آموزشی درس طراحی مکانیزم های دانشگاه امیر کبیر

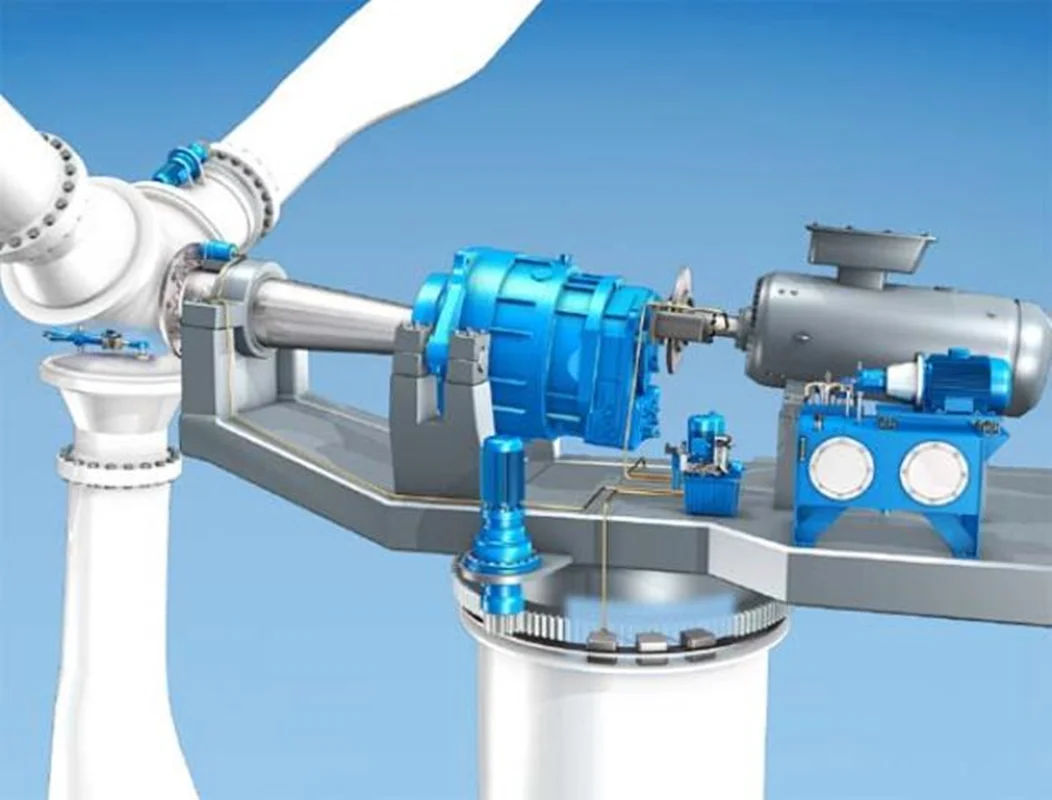

جزوه آموزشی درس طراحی مکانیزم های دانشگاه امیر کبیر پروژه مدلسازی و شبیه سازی توربین بادی مجهز به DFIG و STATCOM

پروژه مدلسازی و شبیه سازی توربین بادی مجهز به DFIG و STATCOM کتاب ماشین های تزریق پلاستیک

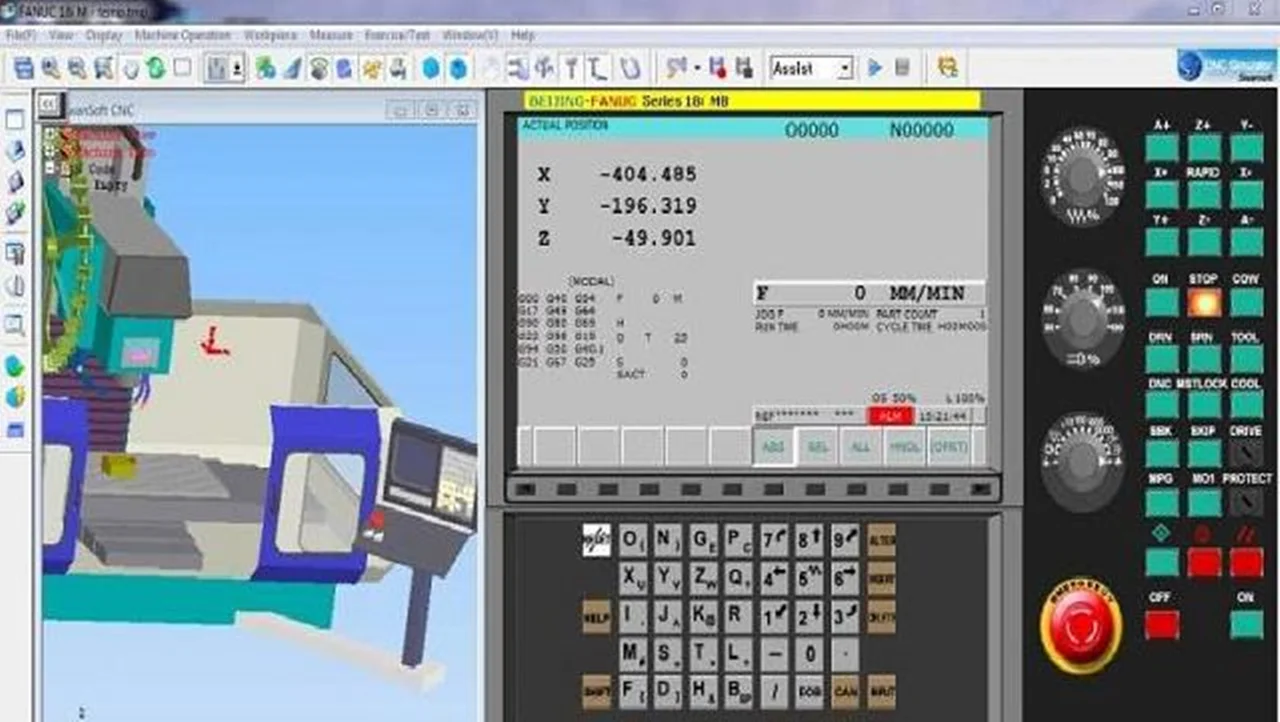

کتاب ماشین های تزریق پلاستیک دانلود نرم افزار شبیه ساز 3 بعدی دستگاه های سی ان سی Nanjing Swansoft CNC Simulator

دانلود نرم افزار شبیه ساز 3 بعدی دستگاه های سی ان سی Nanjing Swansoft CNC Simulator نحوه ایجاد رزوه های اینچی (Inch Thread) در نرم افزار CATIA

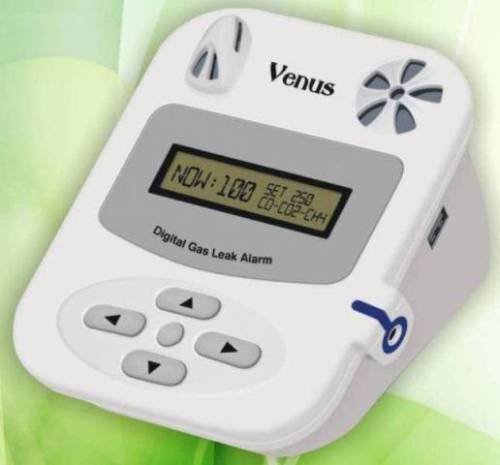

نحوه ایجاد رزوه های اینچی (Inch Thread) در نرم افزار CATIA طراحی سیستم هشدار دهنده گازهای خطرناک بوسیله پیامک

طراحی سیستم هشدار دهنده گازهای خطرناک بوسیله پیامک تحقیق با عنوان: کنترلرها و سنسورها در ماشین های CNC

تحقیق با عنوان: کنترلرها و سنسورها در ماشین های CNC گزارش کارآموزی مونتاژ پراید - رشته مکانیک (گرایش خودرو)

گزارش کارآموزی مونتاژ پراید - رشته مکانیک (گرایش خودرو) کاربرد کامپیوتر در مهندسی (نرم افزار MATLAB)

کاربرد کامپیوتر در مهندسی (نرم افزار MATLAB) آموزش کتیا، کتاب آموزش نکات ضروری در CATIA V6

آموزش کتیا، کتاب آموزش نکات ضروری در CATIA V6